PCB Material

Why partner with COFAN-USA?

- 1. Technology

- 2. Quality

- 3. Responsiveness

- 4. Delivery

- 5. Cost

- Promotion

- View detail >>

SMTA & Final Assembly(OEM)

With our strength of MCPCB, heat sink, assembly and full function design capabilities,

we can provide a one...

> view more

we can provide a one...

> view more

- Contact us

- Go to

contact us >>

- Price Quote

- Go to quote >>

All your quality products supplier.

FR4

Home > Products > FR4

Overview

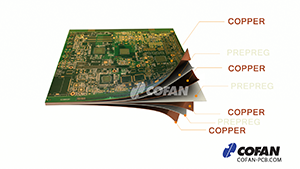

FR-4 is the primary insulating backbone upon which the vast majority of rigid printed circuit boards (PCBs) are produced. A thin layer of copper foil is laminated to one, or both sides of an FR-4 glass epoxy panel. These are commonly referred to as "copper clad laminates."

FR-4 copper-clad sheets are fabricated with circuitry etched into copper layers to produce printed circuit boards. More sophisticated and complex FR-4 printed circuit boards are produced in multiple layers, aka "multilayer circuitry".

For more information

FR-4 copper-clad sheets are fabricated with circuitry etched into copper layers to produce printed circuit boards. More sophisticated and complex FR-4 printed circuit boards are produced in multiple layers, aka "multilayer circuitry".

| Density | Standard | Advanced & Development |

|---|---|---|

| Minimum Line/Spacing - Internal 1/2 oz | .004 | .003 1/3 oz |

| Minimum Line/Spacing - External 1/2 oz | .004 | .003 1/3 oz |

| Minimum Drilled Hole Size | .008 | .006 |

| Minimum Solder mask Web | .005 | .004 |

| Aspect Ratio - Line Card | 12:01 | 14:01 |

| Land Size (Diameter over Drill) | .010 | .008 |

| Thickness (Minimum / Maximum) | 7 / 300 | 5 / 440 |

| Thickness Tolerance | +/- 8 | +/- 6 |

| Layer to Layer Registration | +/- .005 | +/- .003 |

| Minimum Core Thickness | .004 | .003 |

| Minimum Prepreg Fill | .0025 | .002 |

| BGA | .5 mm | .4mm |

| QFP | .5 mm | .4mm |

| Process | Item | Normal SPEC | Special SPEC | |

|---|---|---|---|---|

| Meterial | 150﹎ to 180﹎ | - | - | |

| - | Layer count | 16L | 20L | |

| Mask | Color | Green / blue / Red / Black / White / Golden / Clear | ||

| Silkscreen | Color | White / Black / Red / Yellow | ||

| Testing | 1. Open / Short Testing Spacing | Dedicate: 6ml Fly probe Spacing: 4mil (Smd Pitch: 10 mil) |

- | |

| 2. Open / Short Board Size | edicate: 600x400mm(max)

Fly probe: 640x450mm(max) |

- | ||

| 3. Open / Short Testing Condition | Dedicate: 250V / 50目 / 2M目 Fly probe: 250V / 50目 / 10M目 min / max: 1M目 ~ 20M目 |

- | ||

| 4. Netlist Test | 1). Measure Machine: POLAR 2). Tolerance: ▽10% 3). design: Single End / Differential ▽10% 4). Testing Pitch: 0.254mm |

Tolerance: ▽5% | ||

| Finish Type | HASL Carbon Ink Imm gold Hard gold Imm Tin Leadfree HAL Imm Silver |

Imm Gold+HASL Imm Gold+ENTEK. Carbon+ENTEK Imm gold+G / F(3~30伊) Partial Hard Gold Partial Imm Gold |

Imm Gold + SMOBC | |

| HDI & VIAS | Standard | Advanced & Development |

|---|---|---|

| BBV Mechanical Drill | .010 | .008 |

| Minimum Laser Via (Drill / Capture Pad) | .006/.016 | .005/.014 |

| Variable Depth Laser Via (Depth / Diameter) | .004/.006 | .004/.005 |

| Microvia Aspect Ratio | .5:1 | n/a |

| Impedance / Controlled | Standard | Advanced & Development |

|---|---|---|

| 28 - 260Ohms | +/-10% | +/-7% |

| 50 - 150 Ohms | +/-10% | +/-7% |

| Copper Weights | Standard | Advanced & Development |

|---|---|---|

| Min Outer Base Copper - plated layers | 1/2 oz | 1/4 oz |

| Max Outer Base Copper - plated layers | 5 oz | 5 oz |

| Min Inner Copper Foil - non plated layers | 1/4 oz | 1/4 oz |

| Max Inner Copper Foil - non plated layers | 4 oz | 5 oz |

- Material of FR4

For more information

LinkedIn

LinkedIn Facebook

Facebook YouTube

YouTube Google +

Google +